There’s nothing worse than your boiler packing in just as the weather turns. One day you’re cosy, the next you’re facing a proper freeze-out, no matter where you live in the UK. Our boilers really take a beating from everything our climate throws at them—from the damp air to the hard water. Getting a handle on the most common boiler problems is your best defence. It lets you spot the early warning signs, which can save you a fortune and keep your home safe and warm.

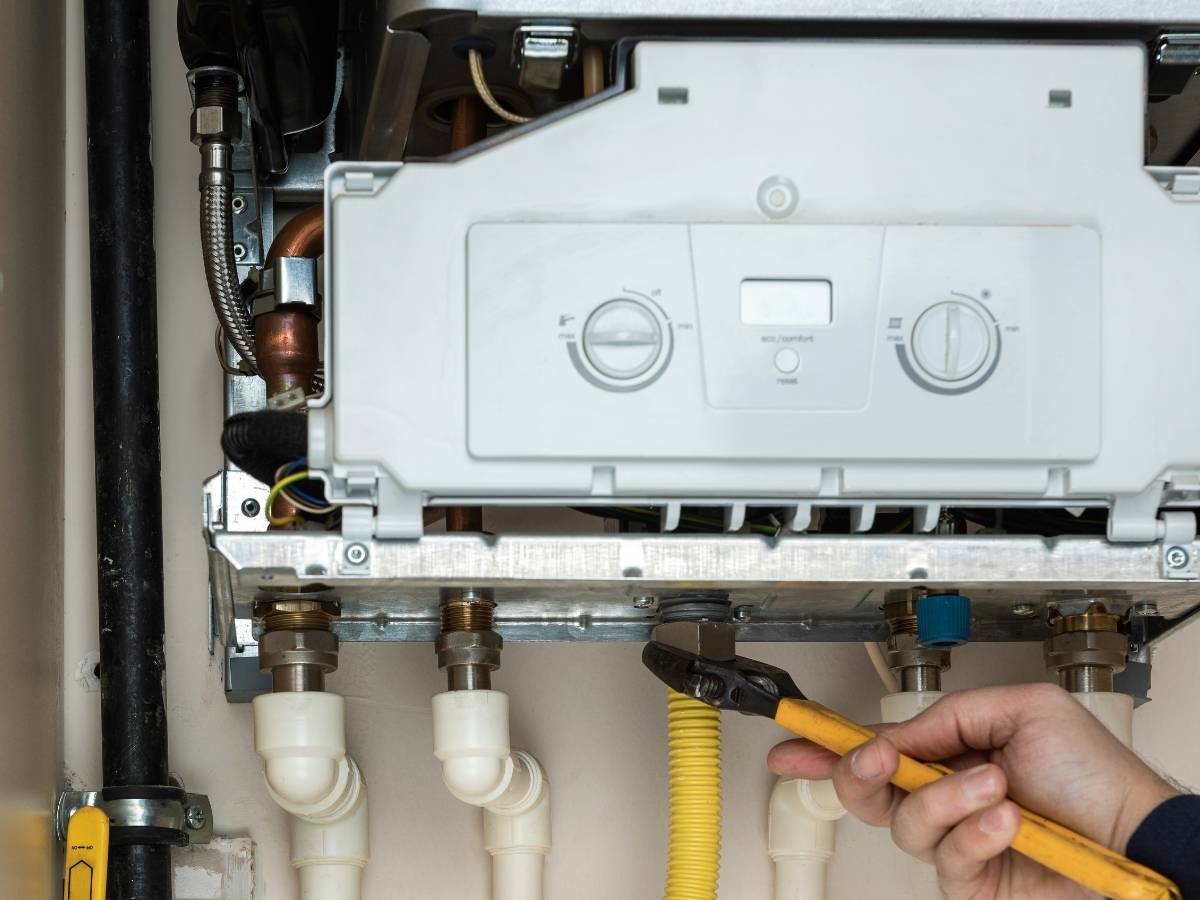

This guide will walk you through the typical faults, what causes them, and what you can do about it, all based on reliable, Gas Safe standards. We’ll also cover how to prevent issues, how to choose the right engineer, and what to do in an emergency. And if you’re based in the North East and need a hand, our team offers boiler repair in Newcastle, handling everything from finding the fault to a full installation.

The Fundamentals: Why Boiler Repairs Matter for UK Homes

Boiler repairs matter because of the following reason:

Stopping Small Glitches

Regular boiler servicing is essential for maintaining central heating systems and preventing minor issues from developing into more serious and costly repairs. Over time, problems like kettling, caused by limescale build-up in the heat exchanger, can reduce the efficiency of your boiler and lead to overheating. Likewise, issues such as your boiler leaking can cause significant water damage to your property.

Ensuring energy efficiency

A well-functioning boiler ensures that it operates efficiently, by Maintaining a reducing energy consumption and lowering energy bills. Regular boiler servicing helps keep the system running at its peak, especially in colder climates where heating is essential for long periods during the year. Regular maintenance isn’t just about safety-it’s also key to lowering your energy bills and keeping your boiler running efficiently.

Safety Considerations

Faulty boilers pose significant safety risks, such as gas leaks and carbon monoxide poisoning. The Gas Safe Register is the official registration body for gas engineers in the UK, Isle of Man, and Guernsey, ensuring that safety standards are upheld. Hiring a Gas Safe registered engineer for boiler servicing ensures that safety standards are upheld.

Spotting and Solving Common Boiler Repair Issues

Before you pick up the phone in a panic, it’s worth knowing that some boiler problems have simple causes you can check yourself. Being able to spot the early warning signs can save you time, money, and a lot of cold days.

Diagnostic Basics: What to Watch For

Think of this as your boiler’s way of talking to you. Learning its language is the first step. Keep an eye (and an ear) out for these common red flags:

-

No Heat or Hot Water: This is the most obvious cry for help. Before you assume the worst, take a quick look at your boiler’s pressure gauge. If it’s reading below 1 bar, it could be a simple pressure issue. It might also be a stuck valve or a problem with your thermostat.

-

Leaking or Dripping: Any puddle or drip around your boiler is a sign something’s wrong. It often points to a worn-out internal seal or a loose connection. A crucial safety note: If water is leaking onto any electrical components, do not touch the unit and call a professional immediately.

-

Odd Noises (Banging, Whistling, Gurgling): Your boiler should be relatively quiet. If it starts sounding like a kettle (kettling), that’s often a sign of limescale or sludge buildup. Gurgling might mean there’s air in the system, while a whistling noise could indicate an airlock.

-

Frequent Shutdowns or Error Codes: Modern boilers will often flash an error code when something’s wrong. For instance, a common code like ‘F28’ typically relates to a flame failure, which could be a problem with the gas supply or a sensor. Keep your manual handy—it’s your best translator for these codes.

While it’s fine to use a multimeter to check basic electrical connections if you’re confident, remember one golden rule: any work involving the gas line, flue, or internal combustion chamber is strictly for a qualified Gas Safe engineer. It’s not just about warranties; it’s about safety.

Step-by-Step Solutions for Everyday Fixes

For those minor, non-gas-related issues, here’s what you can safely try:

-

Low Boiler Pressure: If your gauge is below 1 bar, you can often repressurise the system yourself. Locate the filling loop (usually a flexible silver pipe under the boiler), open both valves until the needle moves to between 1 and 1.5 bar, then close them tightly again. If your radiators are cold at the top, bleeding them to release trapped air can also help.

-

Minor Leaks from Fittings: If you can see a slight drip from a valve or connection, you can try gently tightening it with a wrench. Be careful not to over-tighten, as this can damage the fitting. Monitor it for 24 hours. If it continues, the seal likely needs replacing.

-

Reducing Noise Nuisances: For gurgling radiators, bleeding them is the first step. For louder ‘kettling’ sounds caused by sludge, adding a chemical system inhibitor to your central heating can help. In more stubborn cases, a power flush performed by a professional is the most effective solution.

-

Resetting a Lockout: If your boiler has shut down and is showing a fault light, often the first port of call is to try a reset. Find the reset button (check your manual for its location), press and hold it for a few seconds. Also, a simple clean around the outside of the boiler to remove dust and debris can sometimes resolve sensor issues.

Knowing Your Limits is Key

Your DIY journey should stop at visual checks, basic adjustments, and resetting. The moment you suspect a gas leak, see black soot marks on the boiler, or need to open the sealed combustion chamber, you must call in a professional. Tampering with gas appliances is illegal for anyone without a Gas Safe registration and puts you and your family at serious risk.

How to Pick the Right Repair Path: A Buyer’s Checklist

Finding the right person to fix your boiler can feel daunting, especially when you’re cold and stressed. This checklist will help you cut through the noise and choose a engineer you can trust.

Core Qualifications for Trustworthy Help

This is the non-negotiable starting point. In the UK, any engineer working on a gas appliance must be Gas Safe Registered. Don’t just take their word for it; ask to see their Gas Safe ID card. This is their legal licence to work on gas and proves they have the correct qualifications.

Beyond that, look for experience with your specific type of boiler (e.g., combi, system) and even your brand (like Worcester Bosch or Vaillant). A good engineer will be happy to talk about their experience. Also, check if they offer a 24/7 emergency service—a lifesaver during a winter breakdown.

While national companies are well-known, don’t overlook local engineers. They often build their reputation on personal rapport and repeat business within the community. A quick look at their online reviews can tell you a lot about their reliability and customer service.

The Perks of Choosing a Local Engineer

There are some distinct advantages to hiring a local pro:

-

Speed: A local engineer can often get to you within a few hours, not days. When you have a frozen pipe or no hot water, this speed is everything.

-

Local Knowledge: They understand the common issues in your area, whether it’s the hard water in the South or the damp, chilly climate in the North East.

-

Fair Pricing: Without the large overheads of a national call centre, local engineers can often provide more competitive quotes without cutting corners on quality.

Demystifying Repair Costs in the UK

Let’s talk about money. Transparency is key to avoiding bill shock. Repair costs can vary widely based on the job’s complexity and the parts needed. Here’s a rough guide to give you an idea:

-

Minor Fixes: Something like replacing a thermocouple or a pressure valve is usually at the lower end of the cost scale.

-

Moderate Repairs: Fixing or replacing a pump or a diverter valve requires more time and a more expensive part, so the cost increases.

-

Major Jobs: The most expensive common repair is typically replacing the heat exchanger, the boiler’s core component.

-

Full Replacement: If your boiler is beyond economic repair, you’re looking at the cost of a new unit and installation.

Remember, the age of your boiler plays a big role. Older models (pre-2005) can be more expensive to fix due to obsolete parts. Investing in an annual service is a smart way to keep small issues from turning into major, costly repairs.

What to Do in a Boiler Emergency

Your safety is the number one priority. Know these urgent red flags:

-

Smell of Gas: If you can smell gas (it often smells like rotten eggs), immediately turn off the gas supply at the meter, open windows, leave the property, and call the National Gas Emergency line on 0800 111 999.

-

No Heat in Freezing Weather: If your heating fails during a cold snap, act quickly to prevent your pipes from freezing and bursting.

-

Strange Smells or Smoke: Any unusual smells or visible smoke from the boiler are a sign to evacuate and call for professional help.

In an emergency, a good Gas Safe engineer will give you a clear arrival time. Once the issue is fixed, keep all paperwork for your home insurance, as claims for weather-related damage often spike in winter.

The Importance of Your Annual Gas Safety Check

Separate from a repair, an annual gas safety check is a proactive health check for your boiler. A qualified engineer will:

-

Identify any potential safety hazards before they become dangerous.

-

Check for carbon monoxide leaks, a silent but deadly risk.

-

Ensure your appliance is operating efficiently, which can trim your energy usage.

-

For landlords, this is a legal requirement to obtain a CP12 certificate for your tenants.

It’s a smart habit to schedule this check in the summer, so you’re winter-ready.

Why Expert Repairs Beat DIY Every Time

While it’s great to understand the basics, there’s no substitute for a professional when it comes to gas repairs. Here’s why:

-

They Get it Right First Time: With advanced tools and training, they can accurately diagnose the root cause, not just the symptom.

-

You Get a Guarantee: Reputable engineers will guarantee their labour and the parts for a period of time, giving you peace of mind.

-

It’s Safer: Gas work is not for amateurs. A mistake can lead to gas leaks, fires, or carbon monoxide poisoning.

-

It Extends Your Boiler’s Life: A professional can make holistic adjustments that help your entire system run better for longer.

Stick to simple tasks like resetting the boiler or bleeding radiators. For anything involving the gas supply or internal components, always call a pro. The risks are simply too high.

Conclusion

Choosing the right professionals to look after your boiler is the key to a safe, efficient, and reliable central heating system. By prioritising expert repairs, sticking to a regular service schedule, and considering energy-efficient upgrades, you can ensure your home stays warm and comfortable all year round, without any unexpected surprises.

For trusted and certified heating engineers in Newcastle, the team at Premier Gas is here to help. With a focus on safety, quality, and your complete satisfaction, we provide the expert guidance you need. Let us guide you through choosing the best boiler repair in Newcastle upon Tyne. Contact Premier Gas today for expert guidance and a free quote!