Electric boilers are becoming increasingly popular in UK homes, offering an efficient and clean alternative to traditional gas heating systems. With rising environmental awareness and the government’s push towards net-zero emissions, many homeowners are considering the switch to electric heating solutions. Unlike gas boilers, electric boilers don’t require a flue or gas connection, making them ideal for properties without access to mains gas or those with limited space for conventional boiler installations.

This comprehensive guide will walk you through everything you need to know about electric boiler installation. Whether you’re considering a DIY approach or planning to hire a professional, understanding the process will help you make informed decisions and ensure your installation meets all safety and legal requirements.

What Are Electric Boilers?

An electric boiler is a compact heating appliance that uses electricity to provide both central heating and domestic hot water. Operating on principles similar to electric kettles or immersion heaters, these systems heat water directly through electrical resistance, achieving remarkable efficiency with minimal heat loss.

Types of Electric Boilers in the UK

There are three primary types of electric boilers available in the UK market:

- Electric Combi Boilers: Provide both heating and hot water on demand without requiring a separate storage cylinder

- System Boilers: Work with a hot water cylinder but don’t need a cold water tank in the loft

- Regular Boilers: Require both a hot water cylinder and cold water storage tank, ideal for larger homes with multiple bathrooms

For homeowners in the North East, particularly in areas like Gateshead where properties vary from historic buildings to modern developments, electric boilers can provide an excellent heating solution regardless of gas availability.

Why Choose an Electric Boiler? Key Benefits

Electric boilers offer distinct advantages for UK homeowners, making them a compelling choice for modern heating.

1. Exceptional Energy Efficiency

Electric boilers achieve impressive efficiency ratings, typically reaching 99% compared to gas boilers that rarely exceed 95%. This near-perfect efficiency means almost all electricity consumed converts directly into usable heat, significantly reducing energy waste and lowering carbon emissions. According to the Energy Saving Trust, in well-insulated homes, properly installed electric heating systems can significantly reduce energy bills compared to older gas systems, though actual savings depend on insulation and usage.

2. Space-Saving Design

The compact nature of electric boilers makes them perfect for smaller properties where space is limited. Without the need for flues, gas pipework, or external ventilation, these units can be installed in various locations, including kitchen cupboards or utility rooms. This flexibility is particularly valuable in urban areas like Newcastle where space comes at a premium.

3. Enhanced Safety Features

Without combustion processes or gas pipework, electric boilers eliminate risks associated with gas leaks and carbon monoxide production. This crucial safety advantage means no annual gas safety inspections are required, providing homeowners with greater peace of mind. However, regular electrical safety checks remain essential, as with any electrical installation.

4. Environmental Advantages

When paired with renewable energy sources like solar panels or green electricity tariffs, electric boilers become increasingly environmentally friendly. As the UK’s electricity grid continues to decarbonise, with renewables accounting for over 40% of electricity generation in 2023—the ecological benefits of electric heating systems will only improve over time.

When Should You Install an Electric Boiler?

Electric boilers are ideal in specific scenarios, offering practical solutions for various UK properties.

a. Properties Without Mains Gas Supply

Many rural areas and some urban locations lack gas infrastructure, making electric boilers a practical alternative to oil heating systems. The installation process is typically simpler and more cost-effective than extending gas pipework or installing oil storage tanks. In areas like Durham and Sunderland, where some properties remain off the gas grid, electric boilers offer a viable solution.

b. Smaller Homes and Flats

Well-insulated smaller properties with heating demands below 12kW are ideal candidates for electric boilers. Studio flats, one-bedroom apartments, and compact houses often find electric systems provide adequate heating at reasonable running costs. Research from the National Housing Federation indicates that electric heating can be 30% more cost-effective in properties under 70 square meters compared to traditional gas systems.

c. Homes Seeking Modern Heating Solutions

Properties undergoing renovation or seeking to reduce their carbon footprint can benefit significantly from electric boiler installation. The technology integrates well with smart home systems and renewable energy sources, future-proofing your heating investment.

Planning Your Electric Boiler Installation

Proper planning ensures a smooth installation process and compliance with UK regulations.

1. Assessing Your Property’s Suitability

Before proceeding with installation, several factors must be considered:

- Electrical Supply Capacity: Most UK homes have single-phase electricity supplies rated at 60-100 amps. Electric boilers typically require dedicated circuits with capacities ranging from 20 amps for smaller units to 45 amps for larger systems. A professional assessment from a qualified electrician is essential to determine your home’s capacity.

- Property Size and Heating Demands: Calculate your property’s heat loss by considering floor area, ceiling height, insulation levels, and window types. Well-insulated modern properties typically require 70-100 watts per square metre, while older properties with poor insulation may need 150 watts per square metre or more.

- Insulation Quality: Properties with excellent insulation benefit most from electric heating, as reduced heat loss minimises electricity consumption. Consider upgrading insulation before installation to maximise efficiency and reduce operating costs. The Energy Saving Trust estimates that proper insulation can reduce heating costs by up to 20% annually.

2. Choosing the Right Electric Boiler

Calculating the required kilowatt output ensures your electric boiler provides adequate heating and hot water. undersised boilers struggle to maintain temperatures, while oversized units waste electricity. Professional heat loss calculations consider room volumes, insulation levels, window areas, and local climate conditions. Our guide on how to find a new boiler for your home provides additional insights into this process.

Reputable Brands: Popular UK manufacturers include Elnur, Heatrae Sadia, and Electric Heating Company. Research warranty terms, spare parts availability, and local service support when making your selection. For those considering energy efficiency, our article on 3 energy-efficient boilers to consider in 2025 offers valuable information.

3. Legal Requirements and Building Regulations

Part P of the Building Regulations governs electrical work in domestic properties, including electric boiler installations, must comply with Part P of the Building Regulations. New circuits or modifications to existing electrical systems must be carried out by qualified electricians or competent persons scheme members. Working with Gas Safe registered professionals ensures compliance with all safety standards.

Professional certification becomes mandatory for electrical work beyond basic maintenance. Attempting installations without proper qualifications invalidates insurance and creates serious safety risks. Always verify credentials before hiring installation professionals.

Pre-Installation Preparation: Tools and Safety

Before starting the installation, make sure the following are ready and in place:

Essential Tools and Materials

Electrical tools required for electric boiler installation include multimeters for testing circuits, wire strippers for preparing connections, and various screwdrivers for terminal connections. Professional-quality tools ensure safe and reliable installations.

Plumbing equipment includes pipe cutters for modifying existing pipework, soldering equipment for copper joints, and compression fittings for easy connections. Water pump pliers, adjustable spanners, and pipe bending tools help with pipe modifications.

Safety equipment represents the most critical aspect of any installation. Personal protective equipment includes safety glasses, work gloves, and appropriate clothing for electrical and plumbing work.

Safety Considerations

Electrical safety precautions are paramount when working with electric boiler installations. Always isolate electrical supplies at the consumer unit before starting work, and use proper lockout procedures to prevent accidental reconnection. Test circuits with appropriate meters before touching any conductors, and never work on live electrical systems.

Knowing when to stop and call professionals prevents dangerous situations and costly mistakes. Complex electrical work, gas disconnections, and structural modifications require qualified tradespeople. If you encounter unexpected complications, seek professional assistance immediately. Our article on “Questions to ask before hiring a heating contractor” helps ensure you choose the right professional for your installation.

Step-by-Step Guide: How to Install an Electric Boiler in the UK

Follow these steps for a safe and compliant installation. Always consult professionals for complex tasks.

Step 1: Removing Your Old Boiler

Safely disconnecting existing systems requires careful planning. Start by turning off all utilities and allowing systems to cool completely. Remember that gas connections must only be disconnected by Gas Safe registered engineers.

Drain heating systems properly to prevent water damage during removal of existing equipment. Open drain valves at the lowest points of the system and use pumps if necessary to remove all water.

Step 2: Installing Electrical Connections

Understanding electrical requirements is crucial for safe installation. Electric boilers typically require dedicated circuits protected by appropriate circuit breakers and residual current devices.

Connecting to the consumer unit requires qualified electrical work in most cases. New circuit breakers and RCD protection must be installed correctly to ensure safe operation, with proper building control notification and electrical certification upon completion.

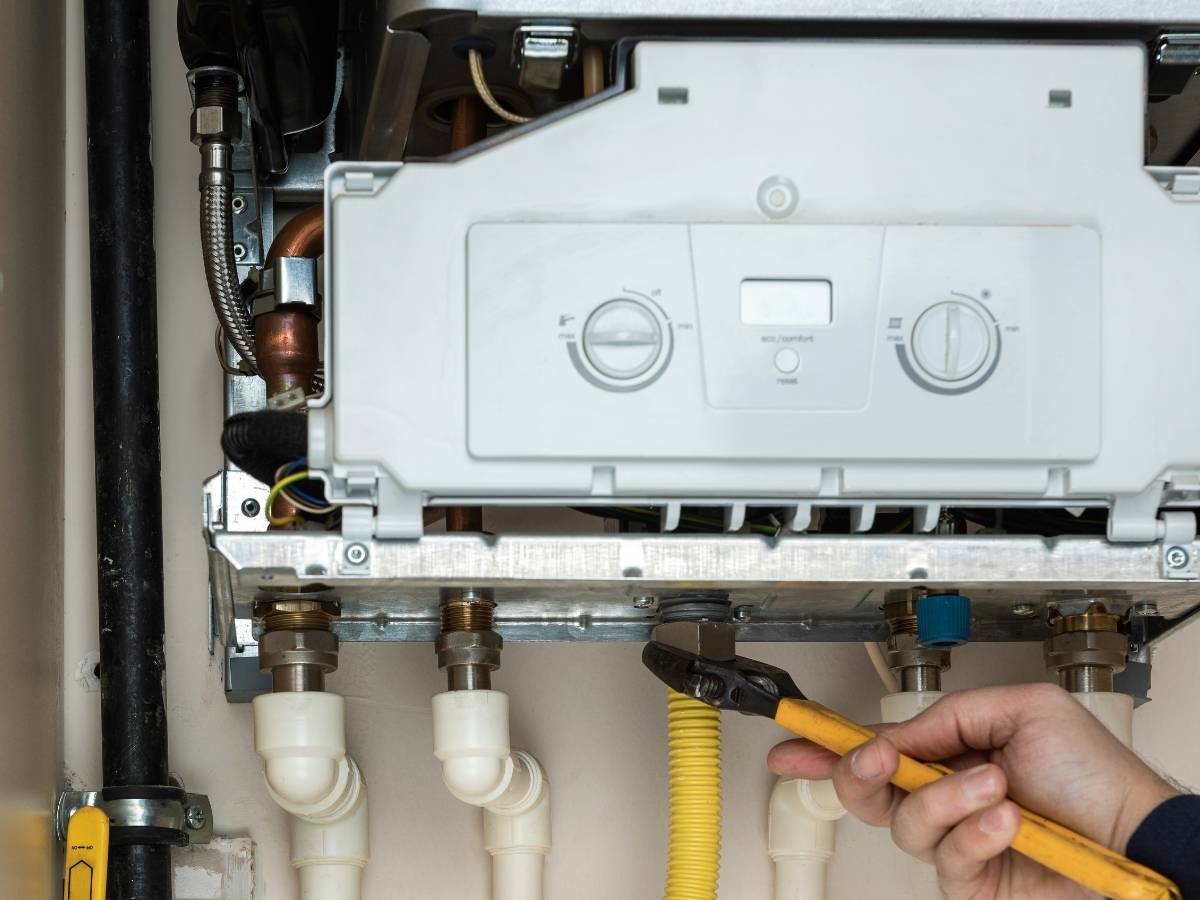

Step 3: Plumbing Connections

Connecting water supply lines requires careful attention to pipe sizing and routing. Use appropriate pipe sizes to ensure adequate flow rates and minimise pressure losses. Install isolation valves on all connections to allow future maintenance without draining entire systems.

Heating system pipework may require modifications to existing circuits to accommodate the new boiler location. Ensure proper pipe sizing for system flow rates and install bypass valves where required.

Step 4: Mounting and Positioning the Electric Boiler Unit

Securing wall brackets requires attention to wall construction and load-bearing capacity. Use appropriate fixings for the wall type and ensure brackets can support the full weight of the boiler plus water content.

Position the boiler unit with careful attention to connection alignment. Ensure all connections align properly before final positioning to avoid stress on pipework and cables.

.

Step 5: Testing and Commissioning

It’s essential to test the system to ensure it operates safely and efficiently. This includes:

Initial System Checks

- Pressure Testing: Test water connections at manufacturer-recommended pressures to detect leaks.

- Electrical Verification: Use test equipment to check continuity, insulation, and earthing.

System Commissioning and Performance Setup

Filling and bleeding the system removes air from pipework and ensures proper circulation. Fill systems slowly to minimise air entrainment and bleed all radiators and high points systematically.

Setting operating parameters involves adjusting flow rates, temperatures, and control settings for optimal performance. Balance radiator circuits to ensure even heat distribution and set heating curves appropriate for the building characteristics.

Final Safety Inspections

Electrical safety checks confirm that all electrical work complies with regulations and safety standards. Test all circuits for correct polarity, earthing, and insulation resistance.

Documentation and certification provide essential records for warranty and insurance purposes. Complete all manufacturer commissioning sheets and obtain electrical certificates where required.

Professional vs DIY Installation

When it comes to installing an electric boiler, homeowners often debate whether to hire a professional or attempt a DIY approach. Each option has its pros and cons, but safety, regulations, and long-term performance should guide the decision.

When to Choose Professional Installation

Complex electrical requirements often exceed DIY capabilities and require qualified electricians. Three-phase supplies, new consumer units, and significant electrical modifications need professional expertise. According to a study by the Electrical Safety First foundation, DIY electrical work accounts for over half of all severe electric shocks in UK homes, highlighting the importance of professional installation.

Building regulation compliance becomes complex when installations involve structural modifications or significant electrical work. Professional installers understand regulatory requirements and can ensure proper certification. For boiler services in the North East, consider our professional boiler service team to ensure compliance and safety.

DIY Installation Possibilities

Simple replacement scenarios offer the best opportunities for DIY installation. Replacing an existing electric boiler with a similar unit often requires minimal electrical modifications.

However, legal limitations and responsibilities must be understood before attempting DIY installation. Certain electrical work requires professional certification regardless of competency levels.

Common Installation Challenges

When installing an electric boiler in the UK, homeowners may face a few common challenges, including:

Electrical Supply Issues

Inadequate electrical capacity represents the most common challenge in electric boiler installation. Many older properties have limited electrical supplies that cannot support higher-powered electric boilers. Upgrading electrical supplies often requires significant work and coordination with electricity distributors.

Professional electrical work requirements increase costs but ensure safety and compliance. Attempting electrical work beyond competency levels creates serious risks and potential legal problems.

Plumbing Complications

Existing system compatibility issues can complicate electric boiler installation. Older heating systems may have pipe sizes or layouts that don’t suit electric boilers. System modifications can be extensive and costly, particularly in properties with complex heating arrangements.

Water pressure considerations affect system performance and user satisfaction. Electric boilers often require different operating pressures than gas systems, necessitating additional adjustments to existing plumbing.

Electric Boiler Running Costs

Before installing an electric boiler, it’s important to understand both the upfront costs and the long-term running expenses. From equipment and labour to ongoing energy bills, these factors determine the true affordability of your heating system.

Installation Cost Breakdown

Equipment costs for electric boilers range from £800 for basic units to £3,500 for high-output systems with advanced controls. Labour costs for professional installation vary significantly depending on complexity and local rates. Simple replacement installations may cost £500-£1,000 for labour, while complex new installations can exceed £2,000.

Additional electrical work expenses can substantially increase total project costs. New electrical circuits, consumer unit upgrades, and supply modifications add considerable expense. Budget £1,000-£3,000 for electrical work depending on existing electrical installation adequacy and boiler power requirements.

Operating Costs and Efficiency

Running cost comparisons help evaluate long-term affordability of electric heating. Electric boilers typically cost more to operate than gas systems due to higher electricity prices. However, high efficiency and lower maintenance costs offset some of this difference, particularly in smaller properties. Our article on energy-efficient heating benefits provides additional context on long-term savings.

Peak and off-peak electricity rates significantly affect operating costs for electric heating systems. Economy tariffs can reduce heating costs by 50% or more compared to standard rates. The Committee on Climate Change estimates that electric heating costs will become increasingly competitive as electricity prices stabilise and gas prices potentially increase.

Maintenance and Aftercare

Keeping your electric boiler in good condition is essential for ensuring efficiency, extending its lifespan, and avoiding unexpected breakdowns. With proper maintenance and timely servicing, you can protect your investment, reduce energy costs, and maintain your warranty coverage. Below are the key areas every homeowner should focus on.

Regular Maintenance Requirements

Annual professional servicing typically costs £100-£200 but can prevent costly breakdowns and maintain warranty coverage. Regular maintenance is essential, as highlighted in our articles on why regular boiler servicing is essential and reasons not to skip annual boiler service.

User maintenance tasks include checking system pressures, bleeding radiators, and testing controls regularly. Monthly checks help identify problems early and maintain system efficiency. For comprehensive maintenance guidance, refer to our essential checklist for boiler service.

Warranty and Support

Most electric boilers include 2-5 year warranties covering parts and labour. Professional installation and annual servicing are often required to maintain warranty coverage. Understanding your warranty terms is crucial, as outlined in our guide on how regular boiler service can save you money.

Registration requirements ensure warranty protection and may provide additional benefits. Many manufacturers offer extended warranties and priority support for registered customers.

Conclusion

Electric boiler installation is a great option for UK homes, especially for properties without gas connections or for those looking to reduce their environmental impact. With proper planning, the process can be straightforward, but understanding safety rules and when to call in professionals is key.

Electric boilers are efficient, low-maintenance, and flexible in installation, making them an attractive choice. Just be sure to consider running costs, your electrical supply, and your home’s suitability before getting started.

Thinking about installation to an electric boiler? Let our team of qualified heating engineers in the North East handle your installation from start to finish. We’ll assess your home’s specific needs, recommend the ideal system, and ensure your installation meets all safety standards and regulations. With our expertise, you’ll enjoy reliable, efficient heating with complete peace of mind. Contact us today for a personalised quote and professional advice tailored to your home’s requirements.